SPOILER ALERT!

Tunnel Pasteurizers Are Highly-Effective Pasteurization Remedies For Foods And Also Drinks

Content author-Dodd Padgett

They are ergonomic as well as lasting, and also they make use of an unique control software program to make the most of performance and lower water usage. This makes sure a high degree of sanitary efficiency. The small layout provides simple accessibility to the components, enabling simple cleansing as well as replacement of inlet screens. Tunnel Pasteurizers can also be used in combination with warm filling strategies, including warm filling up technology.

The Tunnel pasteurizer procedure gets rid of recurring microorganisms from food as well as drinks. They are reliable and be available in different dimensions to suit different needs. They are used in the food and also beverage industries to eliminate microbes, stop fermentation, as well as give shelf stability. Nevertheless, they are subject to high mechanical stress and anxiety and also temperature level variations, as well as damaged bottles can cause damage to the devices. PRO Engineering/Manufacturing has actually been providing the sector with high quality Tunnel pasteurizers for decades and also has constructed many kinds and dimensions.

Tunnel pasteurization is useful for carbonated beverages, which may have a long service life between production as well as usage. Some beverages rest on shelves for weeks before being eaten. They can additionally travel cross countries, spending a period in a cupboard or fridge after acquisition. Hence, Tunnel pasteurization assists preserve quality and taste of these beverages. The process is also beneficial for fragile product packaging, including glass as well as light weight aluminum containers. The sudden change in temperature can bring about the rupture of these containers, which makes it needed to apply the essential preventative measures.

Tunnel Pasteurizers can be utilized to sterilize beverages without chemicals. They make use of a warmth resource, increasing the number of temperature level zones as well as minimizing bacteria. The temperature level is increased up until the required pasteurization temperature is achieved. As soon as Highly recommended Web-site is full, the drink is cooled to prevent any type of prospective damages.

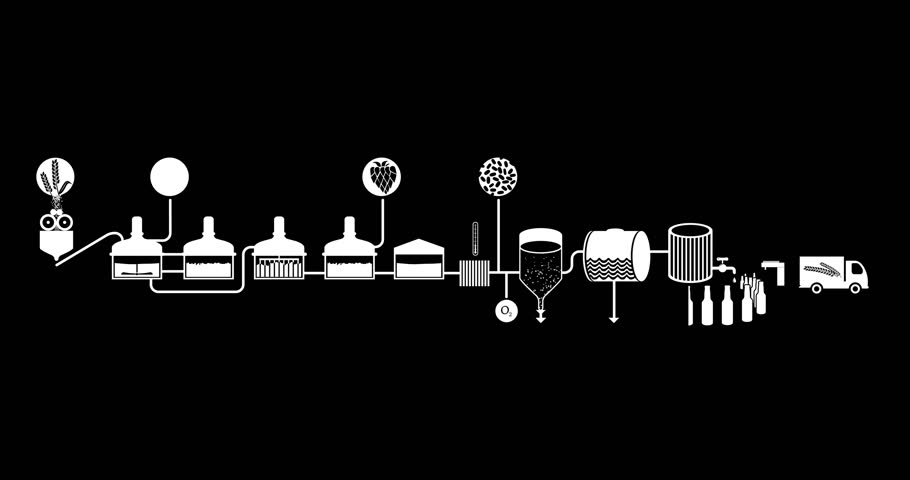

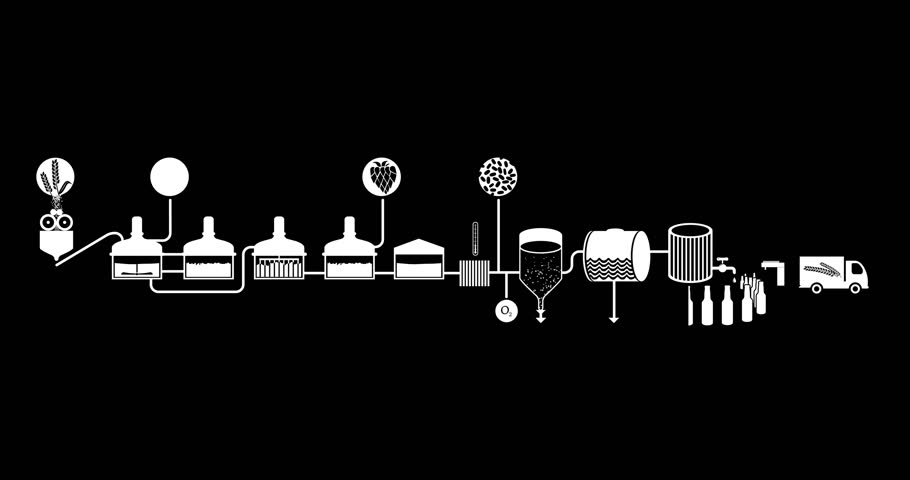

Tunnel Pasteurizers are not just made use of in beverage production, however additionally in the beer sector. Its warmth exchange feature aids recover energy with various temperature zones. Its enhanced nozzle system makes certain great heat exchange with the product. In addition, Tunnel pasteurizers feature water-saving attributes. They collect the water accumulated throughout the pasteurization process, while also maintaining high sanitary criteria.

Tunnel Pasteurizers are an ideal choice for massive production procedures. These systems are a cost-effective, user friendly choice to sterilized filtration and flash pasteurization. They can likewise avoid deterioration of flavor. Some designs feature automatic quit devices to avoid overpasteurization. They additionally can be found in various dimensions and dimensions. They can be tailored to fulfill certain client demands.

Temperature level sensors are a vital attribute of pasteurization devices. They are made use of to establish the pasteurization values. hop over to these guys are done utilizing a formula that determines the PUs. Tunnel Pasteurizers have the ability to check the water temperature with high accuracy. In addition, they are designed for lasting usage. For the best outcomes, temperature level sensors need to be placed at crucial points. Additionally, calibration systems must videotape temperature level as well as stress within the process shipment system.

A passage pasteurizer can be utilized for large-scale manufacturings that have high filler rates. In these cases, a tunnel pasteurizer is required to prevent microorganism exposure to the downstream tools. Using this innovation will permit assembly line to preserve the best requirements as well as eliminate risk of contamination.

They are ergonomic as well as lasting, and also they make use of an unique control software program to make the most of performance and lower water usage. This makes sure a high degree of sanitary efficiency. The small layout provides simple accessibility to the components, enabling simple cleansing as well as replacement of inlet screens. Tunnel Pasteurizers can also be used in combination with warm filling strategies, including warm filling up technology.

The Tunnel pasteurizer procedure gets rid of recurring microorganisms from food as well as drinks. They are reliable and be available in different dimensions to suit different needs. They are used in the food and also beverage industries to eliminate microbes, stop fermentation, as well as give shelf stability. Nevertheless, they are subject to high mechanical stress and anxiety and also temperature level variations, as well as damaged bottles can cause damage to the devices. PRO Engineering/Manufacturing has actually been providing the sector with high quality Tunnel pasteurizers for decades and also has constructed many kinds and dimensions.

Tunnel pasteurization is useful for carbonated beverages, which may have a long service life between production as well as usage. Some beverages rest on shelves for weeks before being eaten. They can additionally travel cross countries, spending a period in a cupboard or fridge after acquisition. Hence, Tunnel pasteurization assists preserve quality and taste of these beverages. The process is also beneficial for fragile product packaging, including glass as well as light weight aluminum containers. The sudden change in temperature can bring about the rupture of these containers, which makes it needed to apply the essential preventative measures.

Tunnel Pasteurizers can be utilized to sterilize beverages without chemicals. They make use of a warmth resource, increasing the number of temperature level zones as well as minimizing bacteria. The temperature level is increased up until the required pasteurization temperature is achieved. As soon as Highly recommended Web-site is full, the drink is cooled to prevent any type of prospective damages.

Tunnel Pasteurizers are not just made use of in beverage production, however additionally in the beer sector. Its warmth exchange feature aids recover energy with various temperature zones. Its enhanced nozzle system makes certain great heat exchange with the product. In addition, Tunnel pasteurizers feature water-saving attributes. They collect the water accumulated throughout the pasteurization process, while also maintaining high sanitary criteria.

Tunnel Pasteurizers are an ideal choice for massive production procedures. These systems are a cost-effective, user friendly choice to sterilized filtration and flash pasteurization. They can likewise avoid deterioration of flavor. Some designs feature automatic quit devices to avoid overpasteurization. They additionally can be found in various dimensions and dimensions. They can be tailored to fulfill certain client demands.

Temperature level sensors are a vital attribute of pasteurization devices. They are made use of to establish the pasteurization values. hop over to these guys are done utilizing a formula that determines the PUs. Tunnel Pasteurizers have the ability to check the water temperature with high accuracy. In addition, they are designed for lasting usage. For the best outcomes, temperature level sensors need to be placed at crucial points. Additionally, calibration systems must videotape temperature level as well as stress within the process shipment system.

A passage pasteurizer can be utilized for large-scale manufacturings that have high filler rates. In these cases, a tunnel pasteurizer is required to prevent microorganism exposure to the downstream tools. Using this innovation will permit assembly line to preserve the best requirements as well as eliminate risk of contamination.